buttons

Click to go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

The Basics of a U.S. Army M1902 AE Luger 9mm FAT barrel Cartridge Counter magazine

A while back a M1902 FAT barrel American Eagle Cartridge Counter Luger magazine was offered by a well-known Midwest dealer, Simpson Ltd for the incredible price of $4,995 and per the listing, subsequently sold.

Although, further input from a very knowledgeable senior Luger Forums On the fakes, it was machined to go past the original button staking hole on the left side of the magazine but they didn't go far enough and the slots were 3 to 4mm too short. A minor detail that they (the mechanics) screwed up, but as we know, the devil is in the details. Additionally, the magazine body dimple and corresponding dimple in the rear edge of the magazine follower is hard to replicate and usually a crude mess on repro CC magazines.

Fake Cartridge Counter magazines have been identified as very good attempts

The two channel, equal length slots in each side of the magazine of a Cartridge Counter magazine body are each approximately 98.4 mm in length. However, the width of the left side pointer slot is slightly wider at 4.2 mm vs the right-side slot narrower width of 3.2 mm. The 1 mm wider width of the added left-side channel slot is to accommodate the 3.75 mm slab sided, horizontally slotted Powell Indicator Device pointer. Pictured is a dimensioned top view of the left side follower, flush mount inlet pointer.

The right-side magazine body slot in a Cartridge Counter magazine to accommodate the Thumb loading button  The lower placement of the left side channel slot is to facilitate the proper alignment of the pointer to accurately align to the proper number of rounds in the magazine as viewed through the isinglass covered, corresponding slot numbered metal strip 1 through 7 in the left-side wooden grip. The lower placement of the left side channel slot is to facilitate the proper alignment of the pointer to accurately align to the proper number of rounds in the magazine as viewed through the isinglass covered, corresponding slot numbered metal strip 1 through 7 in the left-side wooden grip.

The approximately 2.5 mm diameter staking hole on a standard M1900/06 magazine body is situated on the lower left side and aligns exactly with the right-side slot lower termination. With eight rounds inserted in the Cartridge Counter magazine, the left-side pointer sits approximately 8 mm from the bottom of the slot. Regarding the above mentioned fake Cartridge Counter magazines, if the comments are correctly interpreted, for the right side pointer channel slot of the fakes to be correctly positioned on the magazine body, especially at the upper termination of the channel, that approximately 4 mm shorter termination at the bottom of the channel still leaves 4 mm of length below the lowest position of the pointer with the maximum eight rounds inserted in the magazine, would not interfere with the proper functioning of the magazine and the "mistake" appears to be of a cosmetic nature.

Although, addressed as a general comment regarding fake Cartridge Counter Luger magazines in the Luger Forums The Cartridge Counter Wooden GripsThis is a purely speculative analysis as to the how the DWM tool room engineered the modification of the left side grip to accommodate the Powell Indicator Device. While the external dimensions are easy to determine, it is the internal, unseen dimensions or modifications to the wooden grip that are difficult to ascertain without destroying the grip, hence the speculative approach based on observation, logic and common sense. ---------------- page 2 ---------------

The DWM tool room modification of a typical M1900/06 walnut wooden grip to accommodate the Graham h. Powell Indicator Device involved only the left side wooden grip. To fit, i.e., display the pointer required the addition of a channel slot into the wooden grip. As viewed internally, the typical channel slot dimensions are 77 mm long x 3.5 mm wide The exact width of the metal strip is unknown as the rearward edge is suspected to slide/slip in a slot milled into the rearward recessed step. The depth of the rearward edge channel, recessed step had to be deep enough also to accommodate the thickness of the metal strip and the isinglass cover. The thickness of the isinglass, not including the very thin metal strip thickness, is approximately 1.2 mm. This was determined by using the overall thickness of the wooden grip of 7.2 mm, measuring the depth of the internal channel to the underside isinglass surface and measuring the external or outside channel depth to the isinglass top surface and subtracting the totals against the overall grip width.

The calculated 1.18 mm thick isinglass strip was probably inserted in the front channel slot opening by gently pushing it in place by first inserting it completely under rearward recessed lip until the strip seated in the channel (for animation, click here)

A recent February 2021 conversation with Bob Simpson of Simpson Ltd

I asked if he could provide me with some additional pictures of the reproduction Cartridge Counter follower, specifically with two 9mm rounds in the magazine, which would depress the follower down into the magazine, enough to where one could see a left side frontal of the complete pointer in the magazine channel. Interestingly, he also stated that he could not locate the reproduction Cartridge Counter magazine i.e., it is also lost. Apparently, he found the "lost" reproduction Cartridge Counter magazine, as a few days later he posted two additional pictures.

There is a 99% certainty that the Simpson Ltd. $4,995 Cartridge Counter magazine is OK, i.e., authentic, however, it appears that the magazine wooden bottom has been removed, for whatever reason, as the retaining pin edges should be tempered blue, not bright white as is the $4,995 Simpson Cartridge Counter magazine.

The Basics of a M1902 Luger FAT barrel Cartridge Counter magazine

A correct Cartridge Counter Luger follower magazine will have dimple in the rear flat entrance lip of the magazine body, along with a corresponding centered, machined recess in the rear edge of the follower. These two modifications were done by the DWM tool room, possibly to existing production Luger magazines and are purportedly, totally non-functional to the operation of the magazine and pistol. Pictured are four, numbered close-up views of the subject LOB Cartridge Counter follower and magazine. A reasonable conclusion is that these features were added, apparently, in the anticipation of failure, specifically in anticipation of a failure of the follower, so that when replacing a damaged follower, a standard follower without the machined recess wouldn't work, not allowing the follower to properly seat. For an alternate theory for the purpose of the magazine body dimple and rear edge follower machined recess, click here. ---------------- page 3 ---------------

The circular metal discs added to each side of the wooden bottom were simply to assure that the Cartridge Counter magazines were only to be used with a M1902 late Old Model production, short frame[1] Cartridge Counter Luger of which the upper portion of the left side frame grip channel wall was also modified by removing metal by the DWM tool room in order to accept the full insertion of the Cartridge Counter magazine. View 1

Purportedly, as stated above, regarding the Cartridge Counter magazines, the wooden bottom metal discs were added so as indicate that magazines are for use with the Cartridge Counter Lugers only and not specifically to identify the magazine as a 9mm. Furthermore, except for the modified follower and added left side channel slot for the pointer, the magazine is indistinguishable from the plain wooden bottom, .30 Cal magazines, except for the new design Model 1904 shallow feedway entrance lip,

Specifically, an original Cartridge Counter magazine in profile should exhibit a very shallow exit lip contour, forward of the crimped side walls that hold/cradle the 9mm cartridge round. Per TBLAP These changes are clearly evident on other identified 9mm magazines, particularly Cal 9 m/m wooden bottom magazines of which all examined examples, to be authentic, should have the shallow feedway cutaway entrance. Other examples are the German Navy P04 magazines concentric circle wooden bottoms, with or without Cal 9 m/m markings and Portuguese Navy New Model grip safety contract Lugers delivered with Cal 9 m/m marked wooden bottom magazines.

Apparently, the reason for metal discs in the wooden bottoms of the Cartridge Counter magazines, generally interpreted by collectors and some authors to identify the magazine for use with the Cartridge Counter Lugers only, is not completely accurate. For years 10028B, a 4-3/4 inch 9mm Old Model Fat barrel prototype Luger in the collection The Cartridge Counter Luger Pistol, magazine and the Swiss Connection

The identity of the 10028B magazine with wooden bottom circular metal inserts being specifically for the 9mm cartridge, completes the discussion about these 9mm magazine variants that started 63 years ago in 1958 in the Fred A. Datig publication titled: The Luger Pistol, ©1958

Another possibility, considering the above discussion, is while the identically 4-3/4 inch fat barrel configured 10030B was one of three prototype 9mm Lugers submitted May 1903, prior to the April 1904 submitted 50 Cartridge Counter Lugers, to the U.S. Army for consideration, 10028B, although undocumented could have been informally, in the same 1903 time frame, submitted to the Swiss military for evaluation. ---------------- page 4 ---------------

The final and most intriguing example is the earliest known serial numbered GL logo, New Model 9 mm prototype Luger 10051B.

This alternate method of identification will work with the Cartridge Counter magazines, irrespective of other methods of authentication, the Cal 9 m/m marked wooden bottom magazines and any other Old Model magazines. Note, it would be difficult to replicate this feature as one would have to add material, not remove. Pictured are examples of the Old Model magazines

The most significant feature of a Cartridge Counter magazine is the addition of a pointer to the left side of the magazine follower. The pointer had to be flush to the follower edge, requiring a slot or angled channel being machined in the left side wall of the follower, where the upper termination of the basically flat pointer seated flush with the follower surface.

That the designer Georg Luger anticipated failure is possibly political in origin as this ill-conceived pointer request was "hoisted upon" Luger and DWM by Graham h. Powell Original, Excellent Condition Stand-Alone Cartridge Counter Magazine

I acquired an M1902 American Eagle Luger Cartridge Counter (CC) magazine from †Doug Smith of F.G.S. Inc.

Regarding the Cartridge Counter magazine that Bob Simpson's son Brad sold earlier that year for the incredible sum of $4,000, The Smith story seemed plausible at first but after examining my Cartridge Counter magazine in great detail and in an attempt to insert the magazine into the grip of an M1900 Luger, it didn't fit...because the horizontally slotted indicating device mounted on the left side of the follower that protrudes through the added left side magazine body follower pointer slot will pass through the frame metal grip bottom, but interferes or hits the wood interior of the left grip. With the left side wooden grip removed the magazine can be inserted further, but only until the pointer hits the upper metal frame portion of the grip. This made it impossible for Simpson to obtain the magazine in the manner described by †Doug Smith, i.e., it may have been part of the transaction, but the magazine did not come inserted in the grip of a M1900 Luger. Back to The FutureThis is not the end of the story of the provenance of the †Doug Smith acquired Cartridge Counter magazine as one must fast forward to 2021. In the process of writing this article, a search was made of all the identified and most importantly, published pictures of identified Cartridge Counter Lugers and magazines, mostly located through many book publications and auction catalogs in the collection. Of the 50 manufactured Cartridge Counter Lugers, I managed to clearly identify, by actual photographs, about half of the "recorded" Cartridge Counter Lugers, including other heretofore unrecorded examples. ---------------- page 5 ---------------

In perusing an obscure 1993 Butterflied & Butterfield Auction catalog Since there were only 100 unmarked Cartridge Counter Luger magazines made, the odds of identifying one being associated with a specific serial numbered CC pistol, with a published color picture of that pistol is infinitesimally small. This puts to rest the †Doug Smith story of the provenance of the subject Cartridge Counter Luger magazine and creates another mystery how did the subject Cartridge Counter magazine get separated from 22431, assumedly after its sale in 1993, only to reappear in 1997 is unknown, ergo, too many scenarios to contemplate. There are two conclusions to this story: 1) collecting is fun and, 2) don't throw away anything. The Magazine

Presented is †Jan Still's excellent description of the workings of the CC magazine in his book IMPERIAL LUGERS 1991, page 210.

SPECIAL FEATURES: Cartridge counter grips and magazine. The left grip was slotted to accommodate a metal strip painted with the numbers 1 to 7. The strip and slot were covered with a clear materiel (isinglass) The magazine had a narrow slot cut in its left side to accommodate a follower that was situated so it points to the number on the metal strip in the grip that indicates the number of cartridges remaining in the magazine. The magazine has a metal insert in its wooden base and is unmarked. Materiel was removed in the upper left frame channel

The Land of Borchardt in 1997 acquired a spare M1904 Cartridge Counter magazine in excellent condition.

Further inspection of the magazine shows the follower was modified by machining out a slot on the left side of the follower body, 1/2 the thickness of the follower wall and the full height of the follower. This metal strip, with the integral pointer with the horizontal alignment slot was then installed in the machined-out slot of the follower. The fit of the metal strip into the follower is flush with the top and side of the follower slot, extends below the bottom of the follower body with the pointer and was very professionally done in the DWM tool room, similar to the tight fit of the Great Pyramid blocks. The circular pointer is 2.25 mm high and sticks out of the slot in the magazine body about 1 mm. It is more difficult to see the cuts on the side of the follower than the top of the follower, since they coincidentally align with the edges of the added magazine body slot and since the left side of the follower was "blued" or tempered blue/black. Just above the integral pointer, on the added metal strip, can be seen the flush peened/staked shaft end of the domed follower button. The domed follower button has not been relocated or the shaft lengthened, only the manner of peening/staking it as described above. ---------------- page 6 --------------- Obviously, with the added slot in the magazine body the circular tool hole in the lower left side of the magazine body was not needed to peen/stake the domed follower button shaft end to the follower body and since the magazine, in all probability, if it was a new design Model 1904 shallow feed ramp entrance magazine and of recent new manufacture, the 2.50mm hole simply disappeared when the 3.9mm wide by 98.4mm long slot was added to the left side, which is the same length as the existing right side slot, but positioned 5 mm lower on the magazine body. The follower button shaft going through both the main body of the follower and the added slot, then peened/staked, acts to secure the metal strip/pointer, in tension and shear, to the main follower body. Since there is no structural load to the added metal strip and pointer, the retention method used is quite adequate. This modification to the follower should be looked at very closely when examining a cartridge counter magazine as the fakes are usually cruder on this modification. Another modification to the magazine, which is not usually visible in left and right-side profile photos of these Cartridge Counter magazines, is a peculiar dimple or indent in the rear magazine spine at the top, curved entrance and a corresponding dimple or corresponding machined recess or groove in the rear edge of the follower.

It should be noted that as of 1997 the mechanics of the Cartridge Counter magazine was only first generally discussed in a 1993 publication titled: U.S. Military Automatic Pistols 1894-1920 The magazine, if genuine, since regrettably this Parabellum variant has been the subject of faking in the past, has an indentation approximately 3 mm long at the top of its rear spine with a corresponding groove in the rear face of the magazine follower which mates with this. This feature has no function at all in the operation of pistol or indicator; it serves solely to prevent inadvertent replacement of the special follower during repair with a standard pattern without the indicator peg, which will jam on the rear wall indentation before reaching the magazine lips. If this was the purpose of the magazine rear wall inside bulge to prevent someone from putting in the wrong follower, as stated by Sturgess, then why wouldn't the designer have put the bulge at the bottom of the magazine body, making it impossible to even put an incorrect follower into the magazine at all. Since, as Sturgess unwittingly argues against himself, it is exactly the jamming issue, which is caused by the rear wall of the follower riding over the magazine entrance lip sloped protuberance, that an incorrectly installed follower is pushed upward and forward, resulting in the binding of a standard, unmodified follower against the forward curved magazine wall. It is ironically, this predicted binding situation that augers against the Sturgess stated purpose of the bulge and corresponding recess in the follower rear wall to prevent the incorrect insertion of an unmodified follower, it doesn't, which leads us back to the real reason for the magazine inside rear wall entrance lip sloped protuberance, which is explained below. Another approach to further explain the issue, is that with the location of the bulge at the top of the magazine, an incorrect follower could be installed, along with the wooden bottom with spring, which would compress slightly more without effort, could be inserted and the wooden bottom installed, anchored to the magazine bottom with the pin, while not being aware that the follower was seated/stuck just below or possibly, slightly higher into the spine or rear wall "bulge", it isn't until, in the attempt to load the magazine does the incorrectly installed standard unmodified, jammed follower reveal itself. ---------------- page 7 --------------- Alternate Theory or the Battle of the Bulge,The external magazine indent in the rear magazine wall entrance lip, sometimes referred to as a bulge, in actuality, is a sloped protuberance on the inside rear wall of the magazine, located exactly at the rear wall, semi-circular cut entrance lip, which engages the upper cartridge rim edge, functions to give the rising or exiting cartridge a forward "push or assist", thereby guarantying a positive engagement of the cartridge rim by the underside breechblock leading lower edge, propelling the cartridge forward into the magazine feed ramp and into the chamber.

Here is an animation that shows the cycling of rounds through the bulge of the Cartridge Counter magazine. Watching the animation, you notice that the round cannot be propelled into the chamber, it must be stripped off by the breechblock. The top of the magazine walls curl in to capture the cartridges and keep them from falling out or being pushed out by the spring in the magazine body. Therefore, the cartridge is pushed up to under the breechblock and then a little further as the breechblock recoils so that the round is ready to be picked up by the breechblock as it comes forward.

The added forward position of about 1 m/m enabled by the added dimple, viewed externally or alternately, viewed internally as a protruding, sloped protuberance, thought needed because of the heavier 9mm cartridge and since these 50 Cartridge Counter Lugers are the first short frame 9 mm manufactured FAT barrel Lugers, possibly associated with feeding problems. Although, there are a few reported commercial FAT barrel Lugers, with lower serial numbers, of dubious authenticity, made before the 50 Cartridge Counter series, however, the bulk of the higher serial numbered American Eagle commercial 9mm FAT barrel Lugers were manufactured later.

This rear wall magazine internal bulge and corresponding magazine follower machined rear recess in relation to the magazine is ironically associated with the cycling of ammunition through the magazine, starts with a machined recess or scallop in the gripstrap rear wall entrance.

Coincidently, this rear gripstrap wall entrance machined recess isn't unique to the Cartridge Counter Lugers as this machined recess is on all 1900 Old Model Lugers as the cartridge rim of the 7.65mm bottle neck round, being identical in diameter to the 9mm round, had the same issue. Pictured are the rear gripstrap entrance of 1898 Borchardt Luger 5, 1899 Borchardt Luger 23 and M1902 Cartridge Counter Luger 22414 showing the progression of this feature. The gripstrap rear wall entrance of the twenty Swiss Test Trials Borchardt Lugers have a barely discernable wide, shallow depth scallop, which was made narrower and deeper in the Old Model production Lugers. Interestingly, once the fully loaded magazine is inserted into the gripstrap magazine channel, the upper rim of the top round is forced flush to the gripstrap rear wall with the other rounds below it flush against the internal magazine rear wall and maintains that position with the magazine fully inserted. It is after the first round is manually chambered and fired that the next in line, spring propelled round will be pushed slightly forward by the effects of the bulge. Therefore, with the positioning of the first cartridge further to the rear in the magazine did not have an issue of chambering, as the first round was chambered by manually pulling back the toggle knobs to their rearmost extension, engaging the breechblock lower leading edge and releasing, propelling the first cartridge round into the barrel chamber. It is the next and successive rounds that required the boost provided by the rear magazine internal wall exit bulge to effect positive chambering.

Another issue regarding the chambering and cycling required the modification of the magazine exit cradle/lip, which had to be modified to accommodate the straight wall cartridge and larger diameter 9 mm round. For more detail see TBLAP V3, C19 Fig. 19-147

Note that while the Old Model, long frame 10000B prototype 9 mm Lugers, presented to the U.S. Army in 1903 for evaluation How much or fast the exiting cartridge is pushed forward by engaging the internal Cartridge Counter magazine channel rear wall, sloped bulge depends on the strength of the force of the coiled magazine spring and resulting, instant upper acceleration or velocity of pushing the cartridges up the magazine channel, but it seems substantial, at least initially, as with eight rounds loaded, the magazine spring is in full compression. As each cartridge moves up the magazine channel and with the spring releasing its energy, not being a linear function, the upward force is somewhat diminished as the last cartridge is expended.

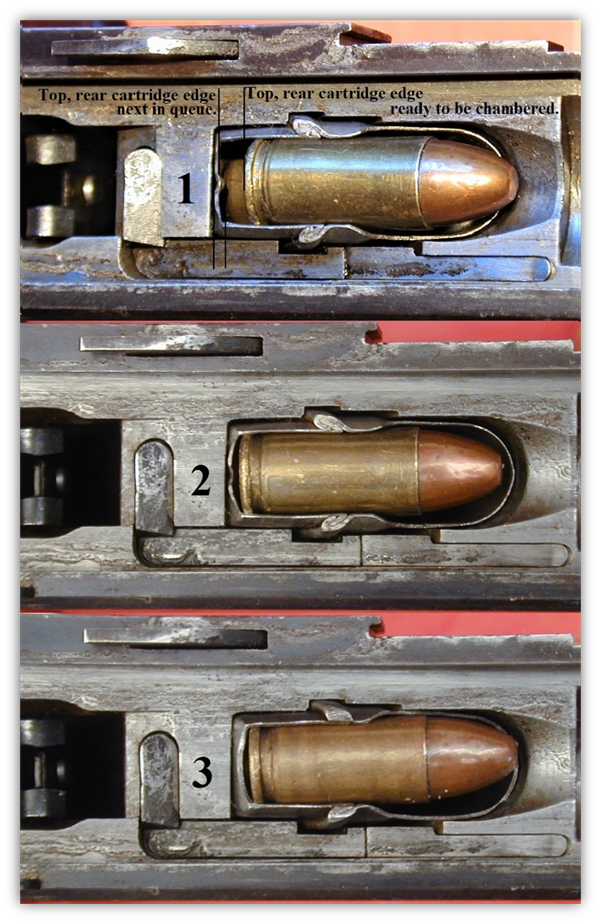

This issue of how fast the exiting cartridge is pushed forward is compounded by the fact, as stated earlier, that the weight of the new 9 mm round is 12 grams vs. the 10-gram weight of a 7.65 mm bottle neck cartridge round, ---------------- page 8 --------------- The magazine body rear wall curved entrance lip, internal sloped bulge and corresponding indent in the rear edge of the follower, assumed by collectors, to be merely for noninterference with the internal magazine bulge. Apparently, this specific pointer unrelated modification, apparently considered ineffective, became unnecessary, as this limited series of Cartridge Counter Luger magazines were the only ones so modified. Additionally, with many rounds expended through a Cartridge Counter Luger during the U.S. Army test program, one would expect to see some Luger Cartridge Counter magazines with the internal, rear wall entrance lip bulge severely worn down, if not completely worn through. Pictured are three top views, numbered 1, 2, 3, inserted in the 22414 frame with a caliber 9 mm, eight round, fully loaded Cartridge Counter magazine inserted.

The distance of the pictured upper cartridge in view 1 was manually moved forward for visibility of the next cartridge in queue is arbitrary and doesn't represent the actual distance resulting in the effects of the bulge, which is very interesting as it was impossible for the designer, G. Luger to know exactly how much, being an internal function, the bulge propelled the cartridge forward, if at all, to get or effect the desired results/benefits, without much experimentation, assumed to be a goal of a complete functioning, no-jamming, cycling operation. The reason for the above discussed modifications to the rear gripstrap wall entrance indent and the cartridge Counter magazine rear wall entrance internal bulge and corresponding follower machined recess were required because of the 55.5⁰ grip angle, with the loaded magazine rounds being inserted in the magazine, parallel to the upper frame receiver and barrel. Which, because of the angle, created the rear upper portion of the top cartridge rim to protrude beyond the rear wall of the magazine, while the upper rim of the remainder of the cartridges contacted the magazine internal rear wall as they cycled up the magazine.

The above discussion could be considered hyperbole by an over active mind regarding the modified Cartridge Counter magazine body rear wall, inside upper lip sloped bulge and corresponding magazine follower rear edge machined recess, as the changes discussed has been stated by at least one author to be non-functional, however, the changes cited did/do have an effect, apparently considered negligible, as not mentioned in any records or notes by the designer, on the cartridges, even though it is undeniable that they do encounter the bulge.

Interestingly, as stated by Sturgess in The Borchardt & Luger Automatic Pistols

In Pistole Parabellum ---------------- page 9 --------------- A Jamming Session

An example, possibly associated with the misfiring and/or jams encountered during the U.S. Army test program can be seen in Cartridge Counter Luger 22411 where damage occurred to the Cartridge Counter forward magazine shallow feedway cut-out as evidenced by an impact depression of an apparently, improperly positioned or faulty 9mm round, against the inside magazine edge wall and accompanying distortion on the magazine exit tip.

The damage to the magazine could have been worse if not for the fact the magazine forward curved edge rested against the forward gripstrap frame wall, just below the frame feed ramp, which is the normal seating position of the Model 1904 magazine at full insertion. This is intentional by design and is to provide complete support of the relatively thin wall, sheet metal construction of the magazine body, which didn't always succeed.

It is difficult to determine if the damage was the result of a single incident or whether the round continued to be propelled into the chamber or the impact resulted in a jam or misfire. This type of damage or problem had been dogging DWM and Luger since the beginning of Old Model production, as evidenced in three early production .30 Cal flat follower button magazines in the collection with basically the identical damage.

Another interesting, but subtle observation when comparing Cartridge Counter magazine 22411 against 22431 magazine is the differences in the followers machining, which is the slight differences in the addition of the pointer to the left side of the follower where the top left edge of the follower and inserted pointer has a slight step or chamfer, while the same area in the 22431-magazine follower does not.

Additionally, the top edge of the 22411 added pointer is decidedly black, where the 22431 added pointer top edge is white metal. There is no doubt that both, similar condition Cartridge Counters are totally authentic and correct, however, suggesting minor machining nuances or inconsistencies in the one-hundred, hand-made Cartridge Counter magazines. With very few examples, these differences tend to make it more difficult or confusing when determining the authenticity of a particular Cartridge Counter magazine. Also, note the slight differences in the magazine rear wall dimple in both examples, where 22431 is the more convincing. 1904 Cartridge Counter Luger feed jam demonstrated.

A fully loaded Cartridge Counter magazine loaded with 8 rounds of deactivated 9mm ammunition

In examining the jam, it appeared that the third round failed to rise or rise sufficiently to engage the breechblock thereby allowing the breechblock to ride over the cartridge, further forcing the round down back into the magazine, resting against the magazine exit forward curved wall. Pictured is a partial view of the left side of 22414 showing the partially cycled toggle link assembly and the five remaining 9mm rounds in the magazine as indicated by the pointer.

This recreated jamming failure in 22414 pretty much replicates the pictured impact/indent damage to the magazine curved forward exit inside surface, immediately below the distorted edge of the fully inserted Cartridge Counter magazine in Cartridge Counter Luger 22411.

An inspection of other 9mm fat barrel Lugers in the collection revealed another possible jamming issue. The barrel feed ramp of a very low series 22000 serial number fat barrel Luger that preceded the Cartridge Counter Lugers showed damage from multiple impact indentations. Note that animation 1 is of an unmodified M1904, 9 mm magazine without the bulge in the magazine body, not for a Cartridge Counter Luger. The failure illustrated in the animation is the same as for the modified Cartridge Counter magazines with the added bulge. This shows that the added bulge did not solve the feeding/jamming issue. Additionally, the failure demonstrated in the animations can occur in any FAT barrel Luger Cartridge Counter or commercial without visible damage to the barrel feed ramp as demonstrated in animation 2. While no picture of a Cartridge Counter showing damage to a barrel feed ramp is available, the Cartridge Counter Luger jamming/feeding issue is well documented in US Army archives. However, the jamming/feeding issue did or may not have resulted in visible damage or contact impact to the Cartridge Counter barrel feed ramp.

This is the first instance of actual damage to a fat barrel component, as damage noted to date are to the Cartridge Counter magazines only[3]. That is not to say that there are no other, non-magazine related feeding issues with the Cartridge Counter Lugers, only that the pictures available of most Cartridge Counter Lugers are generally external. It is of good fortune that the few internal, detail pictures presented herein, being extremely scarce, allowed a cursory analysis, supporting US Army conclusions reached in the 1904 US Army Cartridge Counter Luger Test programs. ---------------- page 10 --------------- Another interesting aspect was discovered when manually inserting or loading of eight, straight wall 9mm cartridge rounds in the Cartridge Counter magazine, in that the first inserted round does not align or conform to the 55.5-degree angle magazine entrance lip, with the bullet pointing demonstrably higher, due the direct influence of the necessary 60-degree angle of the follower cradle or bed. As the second round is inserted the effect of the 60-degree angle follower cradle is less, though the cartridge still does not conform to the 55.5-degree angle entrance.

It is when that the third round is inserted that the effect of the 60-degree follower cradle is diminished sufficiently that the third inserted round and five subsequent inserted rounds conforms to the 55.5-degree entrance lip. Pictured is a progressive view of the first three inserted rounds in the magazine.

When the sixth, seventh and eighth round is striped off the magazine exit cradle, does the approximately 5-degrees higher angle, due to the follower 60-degree cradle exert itself, exerting more upward pressure on the bullet and accompanying additional friction against the bottom of the breechblock, which would create more upward momentum on the cartridge as the rearward propelled breechblock passes over and engages the cartridge rim could result in damage to the barrel feed ramp as illustrated.

The consistency or reliability of the proper cycling of the rounds through the Cartridge Counter magazine could additionally be negatively influenced by the fact that there is no guarantee of proper magazine feed functioning when there is no apparent consistency or proper alignment of the manually inserted rounds in the magazine as evidenced by the eight-round loaded, subject magazine with uneven gaps, positions and angles of some rounds. Serial number 22414 M1902 Cartridge Counter Luger Magazine

Pictured are multiple views of the "Cartridge Counter" magazine

Pictured are Model 1904 magazines 10028B and 22414 in a side-by-side comparison

A close-up view of the magazine entrance of the 22414 Cartridge Counter magazine indicates differences of the modified follower with added pointer, which is evident when compared to the original, authentic 22431 Cartridge Counter magazine follower-pointer assembly. The 22414-magazine rear wall entrance lip dimple is also different from the 22431 Cartridge Counter magazine. The main difference is in the follower pointer assembly and is apparent as viewed in a line drawing of an original pointer assembly vs the 22414-replacement pointer assembly.

It is the bizarre replacement of the pointer and possibly the follower that is interesting as the "aftermarket" replacement pointer is a three-part assembly vs the two-part assembly of an original. See line drawing comparison of an original pointer vs the replacement. ---------------- page 11 ---------------

Looking at a close-up profile of the right-side magazine entrance with a couple of 9mm rounds inserted reveals an additional modification in the form an added block of metal to the bottom of the follower, which is evident when compared to a normal right-side close-up view of a Cartridge Counter follower. As indicated in a standard production follower in the picture is a sometimes-encountered failure of the follower right-side underside support of the Thumb button shaft. The possibility of this type failure could be especially expected in a standard follower, modified to accommodate a Cartridge Counter pointer. Additionally, this type of follower failure, although never encountered or documented before, would not be considered an unusual failure for a Cartridge Counter magazine used extensively in the 1904 U.S. Cavalry Test Trials program.

Since only two M1902 Cartridge Counter Lugers, 22414 Alternately, the 22414 Cartridge Counter magazine could have been a post-test aftermarket concoction as the original 22414 Cartridge Counter magazine was probably destroyed or missing, however, the period condition of the original M1904 magazine body with the aftermarket, poor attempt to replicate the magazine rear wall entrance dimple, it is actually the follower modifications that are way too obvious to fool even the casual Luger collector. Most common and more accurate reproductions were done many years later with the rarity and subsequent meteoric rise in value of the M1904 cartridge Counter Luger and magazines, created the incentive for the mechanics to make fairly acceptable or convincing reproduction magazines.

When they do appear in modern times, they are often in near mint condition and offered for three to four figures. An example is an $810 Cartridge Counter offered by Simpson Limited, wisely described as a reproduction, which looks perfect as first pictured on his web site, It is these two particular mechanical features, as stated by an advanced, knowledgeable collector at the top of this article that are most difficult to replicate. The added pointer and machined left-side follower recess, required to flush mount the pointer strip is also difficult to add, however, are equally difficult to determine authenticity without removing the follower assembly from the magazine body, which would require removal of the wooden bottom. This would ruin the authenticity, reduce the value and collectability of the otherwise assumed originality of the particular Cartridge Counter magazine.

This brings us to the final issue of the originality of the 22414 Cartridge Counter magazine, being the rear wall entrance lip dimple and corresponding added machined recess of the rear follower edge. Pictured are four Cartridge Counter magazine examples of the dimple, which appear slightly different in the four examples. A further test of authenticity or originality is found on the opposite side of the dimple, which is a bulge or sloped perturbance when viewed in profile, described earlier in this article. Unfortunately, the opposite side magazine bulge or sloped protuberance is difficult to see in most pictured examples without lowering the follower to see it. Fortunately, with 22414 and 22431 being in-hand, when lowering the follower, via the thumb button in the magazine channel, one can clearly see the internal bulge or sloped protuberance. ---------------- page 12 ---------------

While the bulge or sloped protuberance is clearly visible in 22431

As stated earlier the condition of the 22414 follower is difficult to explain, where the DWM machined recess to the flat rear follower edge looks to be more of a hatchet job with a gap or crack at the bottom rear, thin wall edge of the follower. The magazine rear wall entrance lip dimple is also suspect. Although, regarding the follower, it could be associated with the overall poor condition of the follower, where it had to be repaired to re-anchor the right-side Thumb button shaft to the follower underside by the addition of a shaped block of metal, crudely soldered in place. In summary, regarding the Cartridge Counter magazine dimple, as externally viewed on/at the magazine rear spine entrance lip, especially viewed in a picture only, is that most Luger collectors have exclusively latched on to that sole feature as a make-or-break item, being the end-all, ultimate factor in determining the authenticity of a Cartridge Counter Luger magazine. With the astronomic rarity and subsequent, ever ascending value in the collector world placed on these magazines, no doubt some creative mechanics have figured out how to apply the dimple, it is therefore, ill advised to solely rely on that particular feature in determining the authenticity of a Cartridge Counter magazine without a detail, in-hand inspection, better yet compared against a known, authenticated example. The only scientific, critical criteria used, to date, by a collector to decide the authenticity of the "dimple" is: Yea, it looks OK to me.

Actually, the dimple is not a dimple, as externally viewed, but a specifically shaped depression with an opposite side sloped protuberance, The impression was applied with a special crimping type tool made by the DWM tool room. This tool could have been in some form of a two-sided dye or cast as the depression cannot be externally applied without deforming the 0.5 mm sheet metal wall thickness, it therefore, has to be applied from both sides under considerable pressure. Furthermore, the externally viewed indent, should be well defined, however, it is the inside wall sloped protuberance that is the functional component, which has to be perfectly shaped with a smooth finish so the cartridge rim can slide past the sloped protuberance with minimal resistance.

Pictured is a crude drawing of a possible crimping type tool used to apply the impression to the magazine rear wall entrance lip. If the sloped protuberance terminated below the entrance lip it would interfere with the smooth transition of the cartridge over the protuberance. The application has to be identical to all 100 made Cartridge Counter magazines to assure consistent functionally and interchangeability, requiring a jigged tool as described above. The purpose of the indent is discussed earlier in the article, however, whatever the purpose, is of little import compared to the fact that it is there.

It interesting to note that all identified, published surviving, stand-alone Cartridge Counter magazines are in excellent to near mint, basically unused condition Also, the same could be said of the surviving, purportedly authentic, unviewed magazines assumed to be correct, inserted in most of the good to excellent condition Cartridge Counter Lugers pictured in this article. It would be expected that the most severely tested Cartridge Counter Lugers tested by the U.S. Army in 1904 that survived, albeit in poor condition, with a magazine, that the much-used Cartridge Counter Luger would correspondingly have a less than pristine Cartridge Counter magazine, such as the 22414 Cartridge Counter Luger magazine. ---------------- page 13 --------------- To the collector or owner of a Cartridge Counter Luger magazine, especially one who has paid a large sum of money, who reads this article and after reexamining his magazine and if differences are noted, the natural inclination will be to take umbrage, citing that not all Cartridge Counter Luger magazines were made identical, which as a general comment is correct, however, it is also true that the DWM German engineers, machinists and technicians went to great lengths to assure that the 100 Cartridge Counter magazines made were sufficiently, dimensionally identical in special features required and essential for functionality and interchangeability in a test program, especially in this case when a large contract is at stake. The Cartridge Counter Lugers M1902 Cartridge Counter Luger 22426 (a.k.a.) also known as: The Three AmigosAs of 2009, Cartridge Counter Luger 22426 was the last unknown Cartridge Counter Luger to be identified, there are yet a few remaining, unknown Cartridge Counter Lugers, however, none have been identified since 2009, noting that the first list of identified Cartridge Counter Luger serial numbers was published in 1972. As the saying goes, everything comes in threes[5]. Apparently, this saying can be applied to Cartridge Counter Lugers as there are three identified Cartridge Counter Lugers with the same 22426 serial number.[6] As described in the 2009 Luger Forums comments, 22426 was authenticated as an original M1902 Cartridge Counter Luger with the major exception of replacement wooden grips, magazine, take down side plate and no grip safety lever. The frame has the expected metal removal in the upper left side grip wall to accommodate the full insertion of the Cartridge Counter magazine left side follower installed pointer. The 22426 American Eagle short frame receiver chamber crest was apparently in poor condition, even before the entire gun was "hot dip" blued, which did not improve its appearance.

Note: Questions were posted to the Luger Forums The ResponseMany Luger Forums members to date have viewed the comments with only one like and one response: Chuck, I have this note in my record of CC Lugers: "On consignment with Simpson, Ltd. Sold to current owner by Richard Ellis. Bob Simpson is not comfortable with the gun, has long felt that it is a fake because of wrong serial number font." Unfortunately, I didn't date that note so I don't remember when Simpson had it. Ron.

A subsequent conversation with Bob Simpson of Simpson Ltd revealed his knowledge of yet another M1902 Cartridge Counter Luger 22426. This example is different from the 2009 Luger Forums ---------------- page 14 ---------------

Example 1 is the 2009 Luger Forums Cartridge Counter Luger 22426 which has been authenticated and accepted by the Luger Forums community as original

In the 2009 Luger Forums

The most informative and revealing comparison is of the last three-digits of the serial numbers on the stop lugs that are of completely different placement and alignment, as are the barrel/receiver witness marks and the full five-digit serial numbers, indicating two different barrels. One possibility is that the PIA barrel serial numbers were restamped on the original Luger Forums

The final determining issue is that the receivers are totally different, with the PIA receiver lacking the receiver underside rails 4mm abutments and full length, 45-degree rail chamfer. This type of receiver with 6mm abutments and shallow 6-degree, full length rail chamfer in the PIA 22426 receiver forks stamped example was not used with the short frame Cartridge Counter Lugers, while the Luger Forums

A comparison of the 2009 Luger Forums original 22426 toggle link assembly

The configuration of the PIA 22426 Cartridge Counter Luger supports various scenarios. There is a strong possibility that it is the restored, original Luger Forums

The original receiver posed issues as the American Eagle chamber crest was in very bad condition, as described in the Luger Forums The second scenario or issue is equally interesting, in as much as the PIA offering description states in one of its many accolades, bromides and general hyperbola in describing 22426 that: The lack of a paper trail for the Cartridge Counter Models points us to a conclusion that several of these guns became "prizes" or presentation guns to individuals of rank and privilege. 9mm Cartridge Counters that have surfaced over the years from private collections rarely show the wear and tear that a calvary troop or testing facility would have inflicted on a firearm. This is the classic Luger, out of an old-time collection, preserved in a minty condition and in dynamite condition. We are offering this "well-documented"[9] classic Parabellum for $50,000.00 to the advanced collector who wants a "top gun" for the collection. In very good condition and offered for $48,895.00 over the counter. ---------------- page 15 ---------------

Keeping in mind that there can only be one original 22426 Cartridge Counter Luger and with the original 22426 pictured, discussed and described in the Luger Forums

Since it is established that the original, hot-dipped reblued 22426, prior to its second "restoration" had standard replacement aftermarket regular wooden grips

The third, or second example, depending on one's point of view, M1902 AE Cartridge Counter Luger 22426 is much easier to define as an aftermarket effort.

Compared to the genuine M1902 Cartridge Counter Luger 22414 receiver underside stop lug, three-digit numeric font stamping and barrel full serial number, clearly shows a different font style, particularly the totally different style of the number "4" used in the 22426-barrel stamping. Regarding the barrel of 22426, the barrel flange is soft and ill-defined suggesting the purportedly "fat" barrel used may have been restored/refinished in the process of applying the five-digit barrel serial number stamping. M1902 Cartridge Counter Luger 22436

With the first 22426 Cartridge Counter Luger(s) in the rear-view mirror, pictured and described is the "other" unknown Cartridge Counter Luger. As the story is told, many years ago, parts of 22436 were found in a box of Luger parts. The main component was the frame, which was/is in reasonable condition. The barrel, obviously being fitted to the receiver in the 1920s or later, separates or disassociates it with 22436. The 530 numbered stop-lug stamped receiver is interesting, as based of the four-lobe factory inspection mark, possibly being serial number 10530. There are, however, American Eagle chambered receivers in that range. The length the barrel and barrel caliber is unknown, except based on the extremely narrow barrel flange, that it was cut-back to fit in the receiver. The inserted toggle link assembly is assumed to be complete, based on the visible stamped 436 middle link underside. Interestingly, the lower front edge of the breechblock underside has been milled flat, possibly indicating a 1904 U.S. Army testing failure, with possibly associated receiver damage, rendering 22436 non-operational or non-functional, accounting for the missing original barrel-receiver assembly. ---------------- page 16 ---------------

Alternately, this area may have been deliberately milled flat for experimentation. The flat, milled recess extends to the forward edge of the breechblock, partially removing the lower section of the Cartridge rim recess wall, meaning that the modification was possibly related to chambering or cycling. In any event this malfunction or deliberate modification probably occurred early on in the testing, accounting for the reasonably decent condition of the 22436-surviving frame.

In reviewing the 22436 breechblock underside modification

This could be related to the U.S. Army reported jamming issue/problem experienced during the U.S Army test program

Note, this condition did not present itself with the Old Model magazine

The dealer states that he has been tempted, more than once to have 22436 restored or sell the parts to a restorer. Collectors be warned! M1902 Cartridge Counter Luger 22436 may yet be reincarnated, offered as "from an old-time collection" for beaucoup or "Boo Koo Bucks", and this time with a near perfect frame, trigger, side plate and toggle link assembly that will need very little "restoration", only the addition of "aftermarket" Cartridge Counter grips, a 9mm caliber fat barrel and receiver in that serial number range and voila, a near mint Cartridge Counter Luger, which will be very difficult to refute and/or authenticate. Although, as a rule, most restorers tend to overdo the restoration to an unreasonable, unrealistic, near mint condition.

BEWARE!!

It should be noted that throughout the Cartridge Counter and later commercial FAT barrel serial number range that the small parts serial number stampings of the take-down side plate underside The Surviving M1902 American Eagle Cartridge Counter Lugers

As reported in Luger Tips

As reported in Central Powers Pistols

The above 2007 Central Powers Pistols Table 60a ---------------- page 17 ---------------

22402, 22404, 22405, 22406, 22407, 22409[10] 22409

As of this writing the following is a list of Cartridge Counter Lugers reported and identified herein by actual photographs:

10078B

In discussing the serial number range of the 50 Cartridge Counter Lugers, collectors tend to go apoplectic, is it 22400 - 22449 or 22401 - 22450? Since †Jan Still in Central Powers Pistols

Posted in the Luger Forum

22450 was known to exist in the early 1990s, but was only first pictured, as stated above, in a circa 2012 Smith & Wesson Forum site ---------------- page 18 --------------- The Other One

The May 4th 2022 Rock Island Auction offered a M1902 Cartridge Counter Luger 22450 which has been determined to be a different Cartridge Counter Luger from the 2012 Smith & Wesson Forum picture of 22450. The differences are apparent when viewing the left-side view of both examples,

When comparing the frame and barrel serial numbers of both examples the differences are readily apparent, especially in alignment and spacing. SummaryIn conclusion, it has been determined by a complete, detailed inspection, internal and external, internal when available, that no matter how persuasive and convincing and authentic a Cartridge Counter Luger is, with its unique Graham h. Powell Indicator Device and inserted Cartridge Counter magazine appears at first glance, and even after an in-hand inspection, one cannot be certain of its authenticity without a detailed, individual part-by-part analysis with full knowledge of the evolution of Luger components, features unique to Cartridge Counter Lugers which includes the receiver-barrel assembly, frame, Powell Indicator Device modified wooden grip, the serialization placement and font styles and the Cartridge Counter magazine. With the above stated criteria, most of the Cartridge Counter Lugers and magazines pictured in this article are assumed to be correct, based on a best effort external examination, lacking the ability, in most examples, of disassembly. The old adage of you can't tell a book by it cover is totally apt for the 50 Cartridge Counter American Eagle Lugers.

Interestingly, the 50 U.S. Army M1902 Cartridge Counter American Eagle crested Lugers are in a rarified category of being the most faked group of Lugers extant, along with their special magazines, second only to the approximately 20 Swiss Test Trials preproduction 1899 Borchardt Lugers with their unique serial number placement and Swiss chamber crests The Luger Forum Musings and 22450Number 22450 is listed in Scott Meadow's book on US Automatic Pistols. Also, this gun came up for sale in 2002 and I talked to the seller (tried to get it down to a price I could afford...NO WAY!) and it is a Cartridge Counter. Probably there is just as much proof that #22450 is a CC as there is that #22400 is a CC, perhaps even more. In addition to the fact that I talked to the owner of #22450, Scott Meadows lists #22450 as a "documented surviving example". He also quotes a May 7, 1904 document by Colonel John F. Greer, Commanding Officer, New York Arsenal..." There were received at this Arsenal on the 20th ult. 50 Luger Automatic pistols with 25,000 Ball cartridges for same". Pretty much rules out the likelihood of 51 CCs being delivered, but doesn't rule out the possibility that #22400 exists regardless of who made it.

[1] It should be noted that the 50 Cartridge Counter Lugers were not the first to use the newly designed, late Old Model production short receiver and 129 mm length frame with wide trigger guard, chambered for the straight wall 9mm round.

[2] Since the identity of the magazines of 10028B and 10051B, with the new Model 1904 design 9mm shallow feedway entrance lips, especially of 10028B with wooden bottom metal inserts, that the new 9mm magazines could have been made before the 50 Cartridge Counter Lugers, hence the possibility of a batch of 50 were "modified" rather that made from scratch.

[3] Although, there is only one Cartridge Counter magazine photograph example showing evidence of damage, with one-hundred made, the probability of more is certain.

[4] M1902 AE Cartridge Counter Luger 22425 is listed in a †Jan C. Still Table 60

as identified and stated to be reblued, which if tested as extensively as 22414 was also probably in bad shape, so much so, that one would resort to a reblue, however, since no pictures or source information are available, diminishes or mutes the value of the information. as identified and stated to be reblued, which if tested as extensively as 22414 was also probably in bad shape, so much so, that one would resort to a reblue, however, since no pictures or source information are available, diminishes or mutes the value of the information.

[5] Folklore professor Alan Dundes said the belief that bad things -- or good things -- come in threes is an ancient superstition that has stuck with us through the ages. He said that all cultures focus on certain numbers as "magical," but Americans have a strong tendency to see things in threes.

[6] Actually, there are only two Cartridge Counters with the same 22426 serial number, however, since the restoration bears no resemblance to the hot dipped reblued "original", being a hybrid combination of reworked original, replacement and new components, it should be referred to as 1A and 1B and 2A, yet another hybrid concoction, hence The Three Amigos.

[7] It is very difficult to identify or associate any restorer to a restored Luger for obvious reasons, however, one particular "restored" Luger has been documented with the particular referenced "noted restorer". The "restored" Luger

was identified by Revivaler was identified by Revivaler to be, purportedly, a 1904 transitional Navy Luger, serial number 726 which was offered in 2017 by Rock Island Auction. Note: this navy variation does not exist, it is a fabrication. to be, purportedly, a 1904 transitional Navy Luger, serial number 726 which was offered in 2017 by Rock Island Auction. Note: this navy variation does not exist, it is a fabrication.

[8] The underside receiver fork abutments and chamfer changed from 6 mm to 4 mm and the full-length receiver forks chamfer changed from 6-degrees to 45-degrees sometimes after serial number 22350 and 22401.

[9] "Well-documented". There is no presented, implied or otherwise, specific documentation, for example, in the form of a certified letter from the consigner or noted personage stating such, to support the provenance of this gun, other than the conviction of the seller, ironically, who states the lack of a paper trail in the description.

[10] Examined by Ron Wood, currently existing in a private collection and in the condition (less than pristine) as originally discovered in 1970.

[11] Appeared on the US market approximately 15 years ago, reportedly in near mint condition.

[13] Rock Island Auction Company sold a 1902 American Eagle Cartridge Luger 22408 with an extensive description titled: Professional Recreation of a DWM 1902 American Eagle "Cartridge Counter" Luger Pistol.

The same pistol was offered again by Phoenix investment Arms. The same pistol was offered again by Phoenix investment Arms.

[14] 22408 frame and barrel serial numbers and inside view of incorrect, aftermarket grips.

[15] Of questionable authenticity.

[16] As first pictured in Luger Variations ©1959.

[17] A classic example of a Cartridge Counter Luger offered by Greg Martin Auctions

being later electronically touched-up compared to its first appearance in the ©1959 publication Luger Variations by Harry Jones. being later electronically touched-up compared to its first appearance in the ©1959 publication Luger Variations by Harry Jones.

[18] Offered again in 2021 by Rock Island Auction as originally pictured in 1959, except in color.

[19] The barrel-receiver witness marks are not aligned when compared against known Cartridge Counter Lugers and the 22422-barrel serial number is located further out on the barrel

and the Cartridge Counter magazine is an aftermarket concoction. Note that the top of the follower (arrowed) has been photoshopped or air brushed, concealing configuration. and the Cartridge Counter magazine is an aftermarket concoction. Note that the top of the follower (arrowed) has been photoshopped or air brushed, concealing configuration.

[20] Identified in the Luger Forum in 2021 as restored with aftermarket grips and without a correct Cartridge Counter magazine.

[21] Probable fake.

[24] Interestingly, the Dutch Luger Book pictures Cartridge Counter Luger 22432 with the following caption: A 9 mm Luger number 22432 with Powell’s Cartridge Indicating Device. This device closely resembles the one invented by the Dutch Lieutenant Vethake for a 1904 trial gun.

[25] Frame only.

[26] Interesting that there are two Cartridge Counter Lugers attributed to Ralph Shattuck, being 22428

and 22440 and 22440 with 22428 with 22428 first pictured in the ©1969 C. Kenyon, Jr. Lugers at Random publication and later auctioned by RIA with 22440 first pictured in the ©1969 C. Kenyon, Jr. Lugers at Random publication and later auctioned by RIA with 22440 pictured in the ©1970 Michael Reese II U.S. Test Trials-1900 Luger hardcover publication. pictured in the ©1970 Michael Reese II U.S. Test Trials-1900 Luger hardcover publication. †Shattuck pictures a Cartridge Counter Luger in his 2000 booklet titled Lugers of Ralph Shattuck †Shattuck pictures a Cartridge Counter Luger in his 2000 booklet titled Lugers of Ralph Shattuck as his, once belonging to the late Mel Torme Collection. as his, once belonging to the late Mel Torme Collection. It is uncertain if it is 22428 or 22440, although it doesn't appear to be either. It is uncertain if it is 22428 or 22440, although it doesn't appear to be either.

[27] December 9, 2022 Rock Island Auction of Cartridge Counter 22445. Note that while 22445 is listed in the ©2007 Central Powers Pistols in Table 60a as "reported"

, this is the first published picture of this Cartridge Counter Luger.

(right side , this is the first published picture of this Cartridge Counter Luger.

(right side ,

left side ,

left side ,

top view ,

top view ,

left grip ,

left grip ). ).

[28] Pictured in U.S. Military Automatic Pistols

©1993 by E. Scott Meadows, page 506, Plate Number 11. ©1993 by E. Scott Meadows, page 506, Plate Number 11.

[29] 22449 as pictured in 1996 Rock Island Auction sale.

|